After the first – partly successful – attempts, however, this form of treatment was pushed back into the background again, as it was quickly discovered that only a small group of patients fulfilled all the basic requirements and that it was also considerably more expensive than conventional treatment methods.

This discrepancy led to a market suppression of the newly emerging treatment ideas.

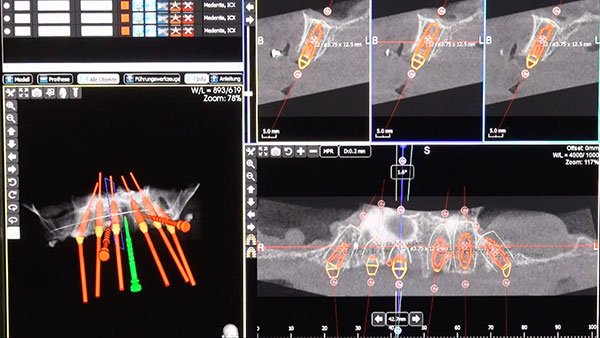

In addition, the radiation doses were still relatively high at the time. It was criticized that these were not in reasonable proportion to the advantages provided by the knowledge of the three-dimensional conditions in the patient’s jaw. The basic prerequisite for surgical planning with prefabricated prosthetics using surgical templates is a prior diagnosis by means of computer tomography, whether by conventional CT or DVT (CBCT).

This was done according to the ALARA principle: “as low as reasonably achievable”.

Due to the market introduction of more and more low-dose and ultra-low-dose devices, the above-mentioned principle has become less and less important in recent years, so that three-dimensional diagnostics can now be regarded as the standard for implantological procedures. This is also shown by the recommendations of the professional associations for the use of such devices for certain indications. Consequently, treatment methods involving direct restoration using implants that have just been inserted (“immediate loading”) are also being taken up again and are becoming increasingly important.

In the field of surgical planning and drilling template production, the use of modern systems with significantly higher precision is becoming more and more prevalent.

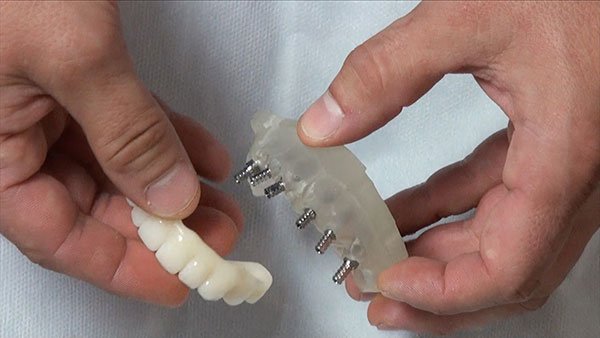

With the ICX-Imperial treatment concept, which consists of the modules of treatment planning with ICX-Magellan and the use of preoperatively fabricated individual PMMA temporaries (ICX-Smilebridge) as well as prefabricated prosthetic components, medentis medical has drawn the logical conclusion from market demand and technical feasibility.

Based on precise data, it is now possible to plan even complex treatment procedures such as implantations after bone reduction or augmentation and to offer temporary solution concepts. Of course, the basic principles of immediate loading are not ignored here either:

Primary stability of the implants (insertion torque of 35 Ncm or more for each implant included in the restoration) and primary splinting (in this case by means of the occlusally screw-retained bridge) must be ensured.